Ex CEMS Sampling Stack Effluent Gas Detector - SO2, NO, NO2, O2, CO2 IECEx Hazardous Area 1,2

Ex CEMS Sampling Stack Effluent Gas Detector - SO2, NO, NO2, O2, CO2 IECEx Hazardous Area 1,2

Couldn't load pickup availability

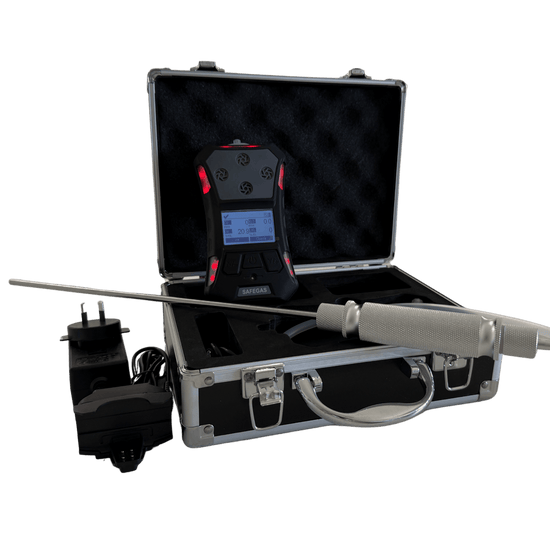

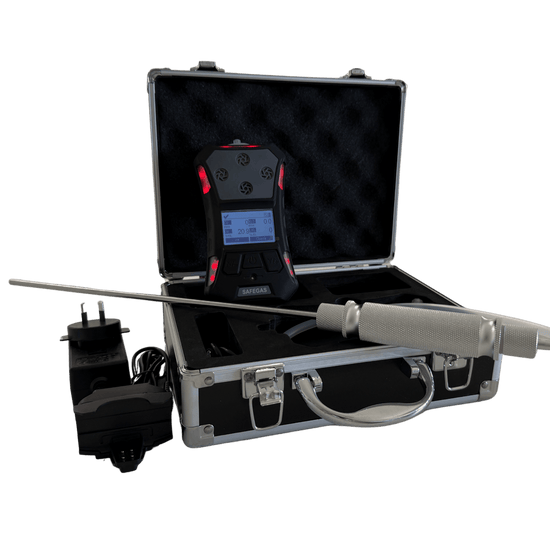

The SKY3000 Hazardous Area Pump Sampling Multi Portable Gas Detector, specifically for the Sampling Stack Effluent Monitoring, sometimes called a stack gas analyzer or CEMS – Continuous Emissions Monitoring System. Is an explosion-proof gas detection monitoring for on the go use for site workers. Engineered to endure and perform in the relentless challenges of the industrial environments with moisture, dirt, dust, corrosion, and vibration.

Harnessing equipment protection levels of Flameproof enclosure "da", Intrinsic safety "ia". Perfectly suited for the most challenging harsh atmospheric conditions, found in industries such as oil and gas, marine, petrochemical, chemical, petroleum. Covered by the IECEx and ATEX certification, brings a compliant solution to hazardous areas.

Collapsible content

Technical Datasheet

Shipping

We aim to process and get your delivery with you as quick as possible -

Shipping rates and delivery times are calculated at checkout.

Guarantee

We aim to provide you with the best quality products, if for an unfortunate product defect we have a 14 day money back return guarantee.

Warranty

• 1 year warranty from the date of purchase.

• Invoice or shipment bill is required to claim the warranty.

• The warranty policy only requires manufacturer to repair the defective product or send substitute for replacement.

• Installation labour, electricity cost and other related cost will not be covered by the manufacturer warranty policy.

• Warranty doesn't cover the defect caused by inappropriate use, especially if directions of the instructions for use are not observed, normal abrasion as well as failures which affect the value or use of the product insignificantly.

Please see our returns policy for more information.

Calibration

To ensure you keep up to date with your metrology requirements, by adding the traceable standards calibration test report certificate.

-

Hazardous Area Certified

Certificates

- IECEx CQM 21.0009X

Equipment Protection Level

IECEx

Ex da ia IIC T4 Ga with LEL sensor

Ex ia IIC T4 Ga without LEL sensor -

Gas Measurements

Measurement of gas concentrations:

SO2 Sulfur dioxide

NO₂ Nitrogen dioxide

NO Nitric oxide

-

Features

- 100,000 local data records and exportable.

- Alarm Audio, Vibration, Flashing Light, low battery alarm, pump block alarm, man down alarm, optional real-time remote bluetooth notification

- Password protection function

- 2200mA Battery +15 hrs use.

- Unit selector PPM and mg/m³

Introduction to the SKY3000 Intrinsically Safe Sampling Gas Detector Analyser

Where Are These Systems Used?

Flue gas emissions monitoring is essential across multiple heavy industries:

- Monitoring NOx, SO₂, CO, and CO₂ from coal, gas, or biomass plants.

- Managing flare stacks and process emissions.

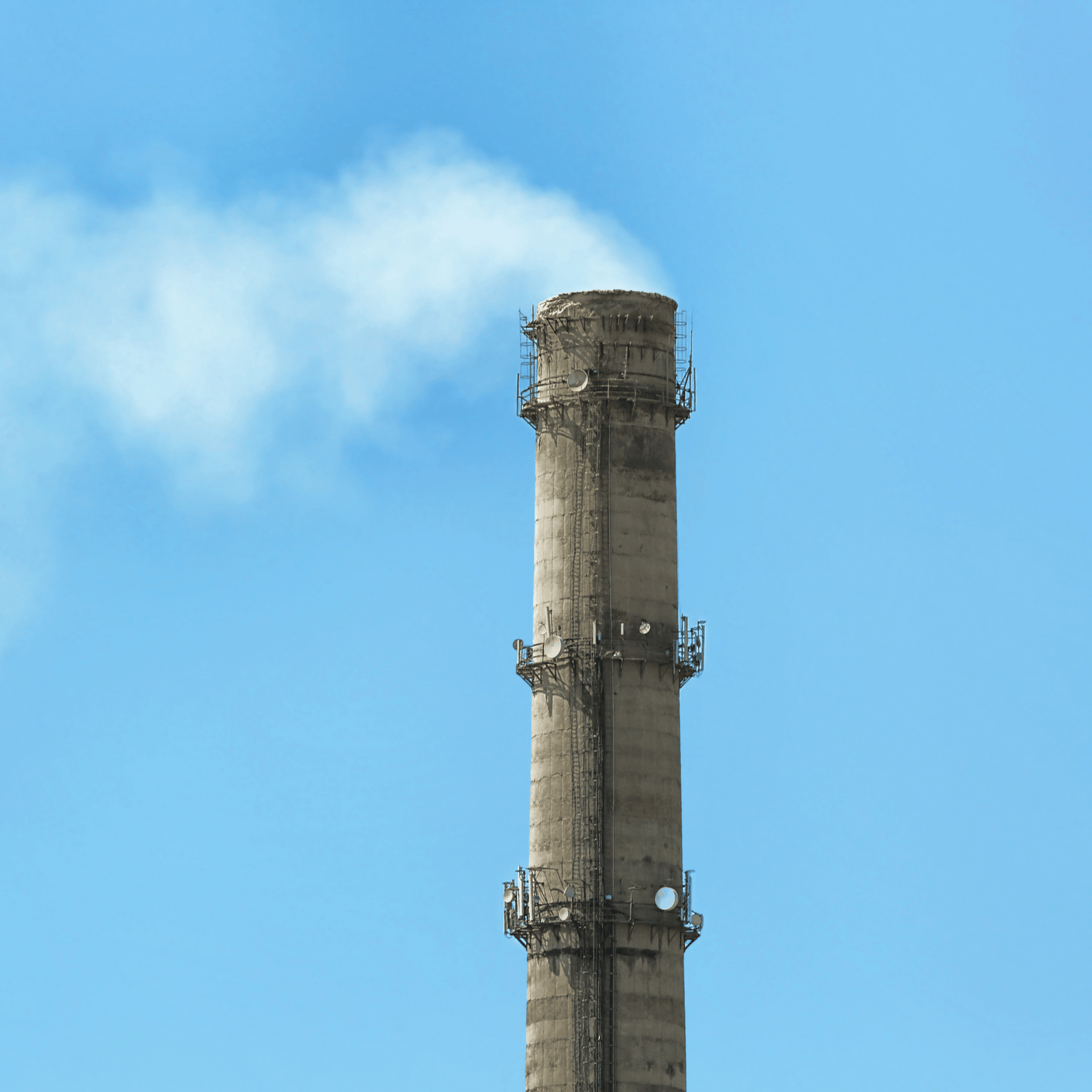

Understanding the Importance of Industrial Flue Stack Effluent Emissions Monitoring

In industries where combustion is part of the process—whether generating power, refining chemicals, or disposing of waste—flue stack emissions monitoring is not just a regulatory requirement, it’s a cornerstone of environmental responsibility and operational safety.

Flue stacks, also known as chimneys or exhaust stacks, release gases produced during industrial operations into the atmosphere. These emissions may contain harmful pollutants such as carbon monoxide, sulfur dioxide, nitrogen oxides, volatile organic compounds (VOCs) and more. Monitoring and managing these emissions is crucial to protect workers, surrounding communities, and the environment.

Why Monitor Flue Stack Emissions?

Regulatory Compliance – Governments impose strict limits on atmospheric emissions. Violating these can lead to fines, shutdowns, or legal action.

Environmental Protection – Many flue gases contribute to climate change, acid rain, or air pollution.

Operational Safety & Efficiency – Gas detection can signal incomplete combustion, system leaks, or process inefficiencies, allowing for faster corrective action.

Industrial flue stack emissions monitoring is a critical aspect of environmental stewardship, workplace safety, and regulatory compliance. From preventing toxic exposure to protecting the atmosphere, the value of a properly designed and maintained gas detection system cannot be overstated.

Gas Calibration Bump Test Kit for Honeywell BW Microclip XT Gas Detectors | H2S,CO,O2,CH4 Bottle

Add Calibration Service

Ensure to keep up to date with your metrology requirements, by adding the calibration test report certificate.

STAY ALERT. STAY SAFE.

- NOx (Nitrogen Oxides) High-temperature combustion. Forms smog and acid rain. Damages lung tissue.

- SO₂ (Sulfur Dioxide) Fossil fuels, smelting. Causes respiratory distress and acid rain. Corrosive to equipment.

-

Pre & Post After Sales Support

After Sales Support

We offer after sales support on all our products including

- Installation

- Configuration

- Maintenance

- Repair

- Calibration

-

Calibration & Repair

Calibration ServicesOur accredited laboratory is tailored to conduct traceable standard calibrations and repairs on all our equipment.

Our Core Values

-

UNPARALLELED SUCCESS

We embrace every challenge as a team with our expertise, and have a proven track record of success when we collaborate.

-

WORK SMARTER NOT HARDER

In order to do great work, we need knowledgeable, well-trained individuals, combined with automation. We are dedicated to not only providing our team with top-notch training, but also world-class equipment to ensure we’re stay at the cutting edge of the industry.

-

TAKE PRIDE

Since the beginning, we have always believed in the quality and longevity of the products we sell and service we provide, and are proud to offer our expertise to all industries.