Mining has long been one of the most dangerous industries, with countless lives lost to hazards like carbon monoxide (CO), methane (CH4), and oxygen depletion.

Methane, a highly flammable and odorless gas, is released during coal extraction as it escapes from coal seams into the mine’s air supply. Without detection, this invisible gas poses severe risks, including fires, explosions, and suffocation.

Similarly, carbon monoxide is a frequent danger, often produced during the oxidation of coal and wood. This colorless, scentless gas can lead to poisoning, with symptoms such as nausea, dizziness, vomiting, headaches, and confusion. In high concentrations, CO exposure can cause unconsciousness or even death.

To mitigate these risks, miners historically relied on crude detection methods, such as using canaries or burning methane wicks to identify gas threats. Thankfully, modern technology has revolutionized safety. Advanced fixed and portable gas detectors now provide reliable monitoring of air quality, safeguarding workers—and sparing canaries—from harm.

Hazardous Areas in Mining

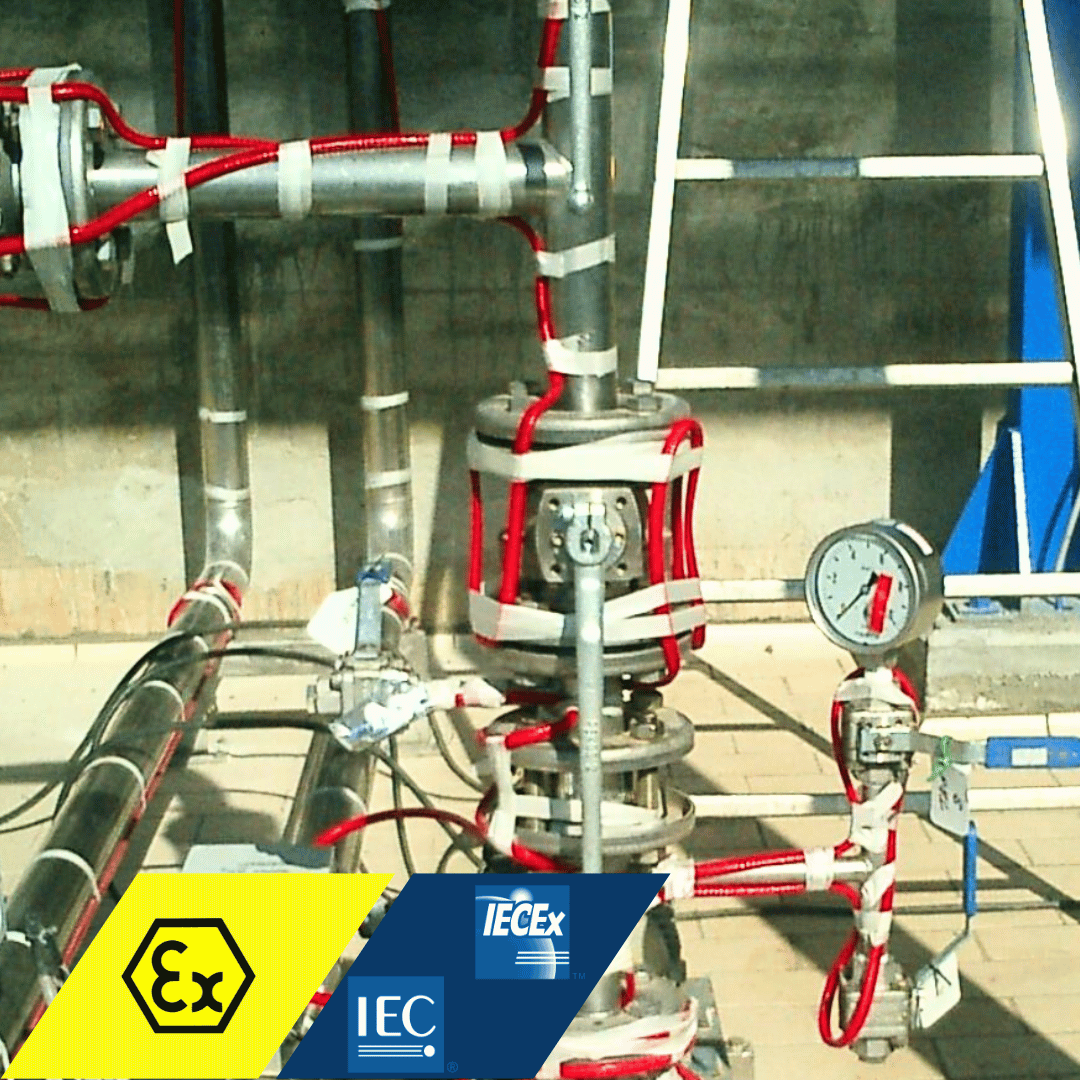

Hazardous underground areas like coal wash plants, reclaim tunnels and conveyor systems where flammable gases are present.

In many cases, coal wash plants and reclaim tunnels are positioned underneath coal stockpiles and are at risk of fire and explosion because of the potential build up of methane gas and coal dust due to coal transportation.

APPLICATIONS

-

Gold Mining

Gold mining frequently relies on hazardous chemicals like cyanide and involves processes that emit harmful gases, such as sulfur dioxide (SO2) during ore smelting or roasting. Ensuring the detection of these toxic fumes and vapors is essential for maintaining safety, alongside monitoring for flammable gases like methane (CH4) to reduce the risk of explosions.

-

Room and Pillar Mining

This method entails carving out large chambers of ore while retaining supporting pillars to maintain structural integrity. Though widely used in coal mining, it is also applied to materials such as gypsum and salt. The enclosed nature of these spaces necessitates careful oxygen monitoring to ensure safe working conditions. Additionally, tracking methane levels is critical due to its flammability risk. Gases like carbon monoxide (CO) and hydrogen sulfide (H2S), common byproducts of mining operations, can lead to asphyxiation, making effective ventilation and continuous gas monitoring absolutely essential.

-

Cut & Fill, Longwall Mining

In these scenarios, managing gas emissions in backfilled zones and areas where extensive sections of coal seams are excavated is critical. Proper ventilation is key to preventing the accumulation of toxic gases like carbon monoxide in confined environments. Additionally, early fire detection plays a vital role, as mining machinery produces heat that, when combined with methane or coal dust, can pose a serious risk of ignition and combustion.

-

Sub Level Stopping, Caving and Shrinkage Stopping

Blasting and caving activities often release hazardous gases like methane, nitrogen dioxide (NO2), and hydrogen sulfide, presenting serious safety challenges. Reliable detection and continuous air quality monitoring are essential to mitigate these risks. Equally important is ensuring that gas detectors are resistant to dust, as excessive particulate matter in mining environments can compromise their functionality.

-

Block Caving

When large quantities of ore break apart, gases trapped within fractures or voids can escape into the atmosphere. Gas detection systems are vital for identifying the presence of methane, carbon dioxide (CO2), and other hazardous gases released during extraction. Like sub-level caving, block caving generates substantial dust and airborne particles, which can reduce visibility and degrade air quality. It is crucial to use gas detectors designed to perform reliably in dust-heavy conditions.