Collapsible content

Technical Datasheet

Shipping

Manufacturing lead time is dependant on quantity ordered. This is excluding the delivery lead time which is estimated at checkout.

We aim to process and get your delivery with you as quick as possible.

Please contact us to retrieve the estimate lead times for your order.

Guarantee

We aim to provide you with the best quality products, if for an unfortunate product defect we have a 14 day money back return guarantee.

Warranty

• 1 year warranty from the date of purchase.

• Invoice or shipment bill is required to claim the warranty.

• The warranty policy only requires manufacturer to repair the defective product or send substitute for replacement.

• Installation labour, electricity cost and other related cost will not be covered by the manufacturer warranty policy.

• Warranty doesn't cover the defect caused by inappropriate use, especially if directions of the instructions for use are not observed, normal abrasion as well as failures which affect the value or use of the product insignificantly.

Please see our returns policy for more information.

-

Hazardous Area Certified

Certification

ATEX n. ECM 23 ATEX-B US48

Protection level marking:

ATEX: Ex II 2 G Ex db IIB T4 Gb

-

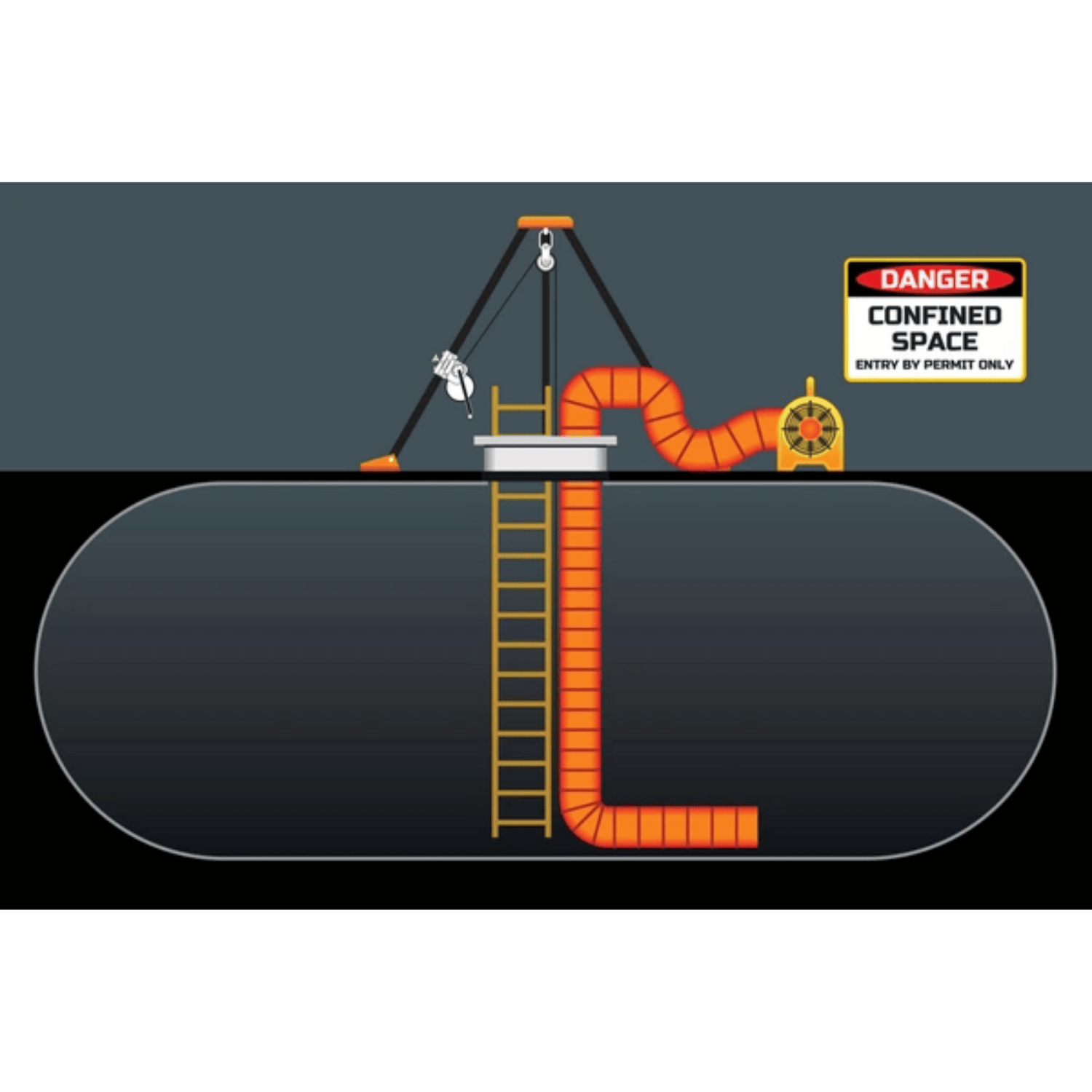

Ventilation

Ventilation is essential in confined spaces when the air quality is unsafe or when hot work creates dangerous fumes. Properly ventilating these spaces can be challenging, and it might be required to divide the work area from the larger environment to improve airflow or ensure workers use respiratory protection in addition to the ventilation.

-

Key considerations

Key considerations include ensuring that the fan is appropriately sized for the space, that exhaust points are located away from entry areas, and that ventilation is continuous during operations. Workers must be trained on the use of the equipment, and respiratory protection may still be required if ventilation is not sufficient. Regular monitoring of air quality and proper communication methods are also essential for safety.

Before entering any confined space, the air inside the space must be checked using a 4 gas mix detector. Ventilation must continue throughout the confined space work.

These meters check oxygen, carbon monoxide, and hydrogen sulfide levels, and check for the presence of flammable vapors in the atmosphere.

- Oxygen: levels must be between 19.5% and 23.5%

- Carbon monoxide: the permissible exposure level over eight hours is 50 ppm and the ceiling is 200 ppm

- Hydrogen sulfide: the permissible exposure level over eight hours is 10 ppm

- Any flammable vapors must be below 10% of the lower explosive limit (LEL) before entry.

Applications of Explosion-Proof Portable Ventilation Extraction Fans with Ducting

-

Confined Space Welding & Hot Work

Confined space welding produces hazardous fumes, excessive heat, and potential ignition sources, making proper ventilation critical. Explosion-proof fans remove toxic welding fumes, reduce heat buildup, and ensure a safe working atmosphere.

Key Applications

- Prevents the accumulation of flammable vapours inside storage tanks and process vessels.

- Extracts hazardous gases from pipelines containing hydrocarbons or chemical residues.

- Ensures safe ventilation in enclosed compartments where welding sparks and gas vapours could ignite.

- Removes metal fumes, flammable dust, and gases from underground welding and cutting activities.

-

Oil & Gas Industry

The oil and gas industry involves handling volatile hydrocarbons, making proper ventilation essential to prevent explosions. Portable Ex extraction fans are used for ventilation during maintenance, shutdowns, and emergency operations.

Key Applications

- Removes hazardous vapours from crude oil, gasoline, and chemical storage tanks before worker entry.

- Ensures safe conditions when welding, grinding, or cutting inside pipelines.

- Ventilates enclosed compartments where explosive gases could accumulate.

- Prevents vapor buildup in enclosed workspaces near flammable gas lines.

-

Petrochemical & Chemical Processing Plants

Chemical plants handle volatile substances that pose fire and explosion risks. Portable explosion-proof fans provide localized ventilation for areas where flammable solvents, dust, or vapors are present.

Key Applications

- Prevents the accumulation of toxic or explosive vapours.

- Extracts solvent fumes and chemical vapours in enclosed spaces.

- Provides airflow in confined equipment rooms with hazardous atmospheres.

- Ensures safe ventilation before worker entry into confined processing tanks.

-

Mining & Tunnelling Operations

Mines and underground tunnels have limited natural airflow and often contain hazardous gases such as methane, carbon monoxide, and hydrogen sulfide.

Key Applications

- Provides airflow in confined shafts and tunnels where gas buildup is a concern.

- Removes hydrogen gas emitted from lead-acid and lithium-ion battery charging areas.

- Ensures proper extraction of metal fumes, gases, and dust in mining maintenance work.

-

Shipbuilding, Marine, & Offshore Facilities

Ships and offshore platforms have confined spaces where flammable fumes from fuel, paints, and welding activities can accumulate. Explosion-proof portable fans provide essential ventilation for safe operations.

Key Application

- Removes residual fuel vapors before maintenance.

- Extracts hazardous fumes and ensures airflow in confined compartments.

- Controls dust and fumes from welding, grinding, and painting.

- Used in enclosed areas such as pump rooms, drilling platforms, and gas compression modules.

-

Grain Silos & Food Processing Plants

Flour mills, sugar refineries, and grain silos generate combustible dust, which can ignite under the right conditions. Explosion-proof fans help reduce dust concentration and prevent ignition.

Key Application

- Provides airflow for workers entering confined grain storage bins.

- Extracts airborne dust from flour, starch, and sugar processing areas.

- Reduces dust accumulation in conveyor and hopper systems.

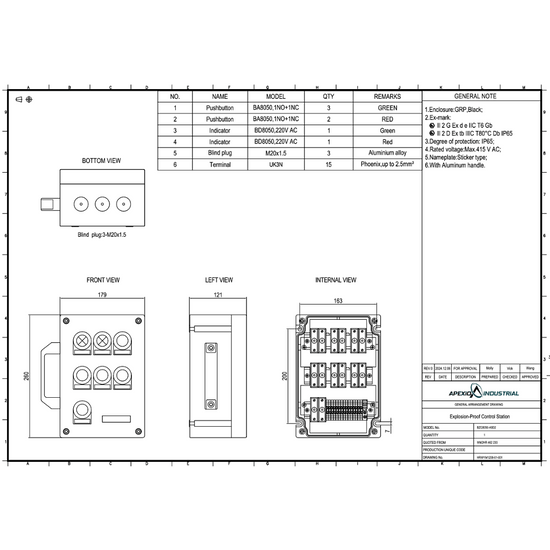

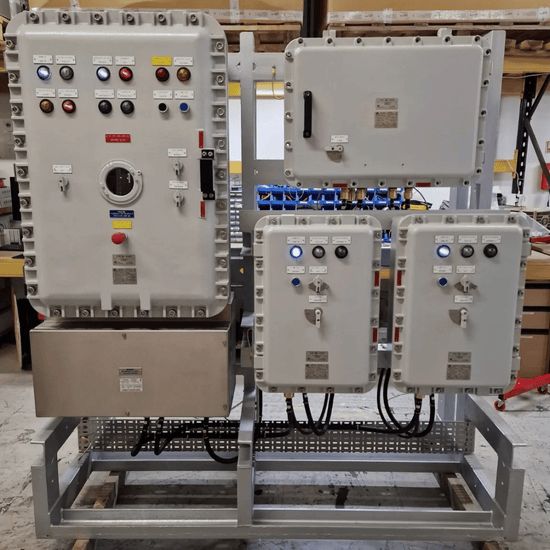

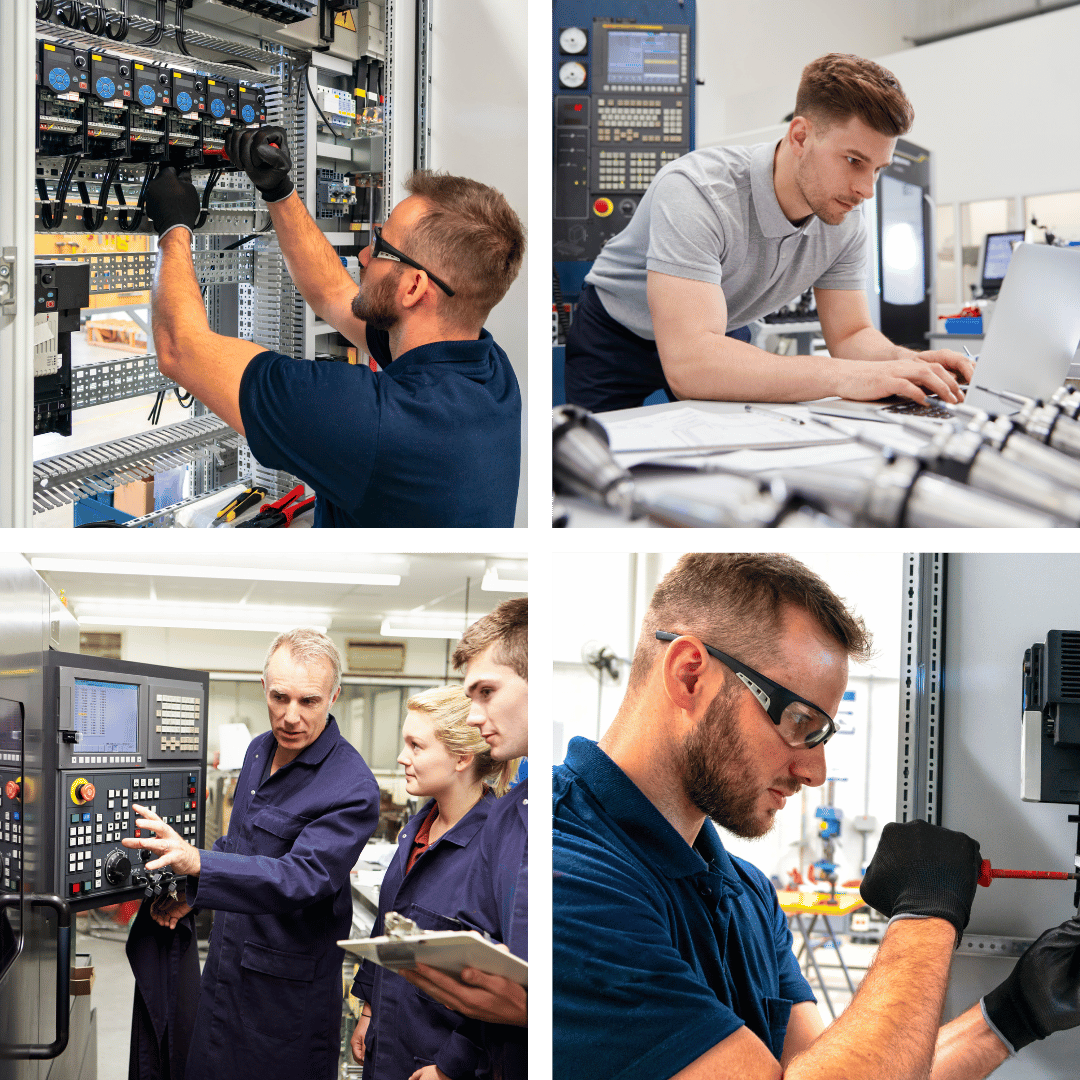

Ex Electrical Manufacturing & Fabrication

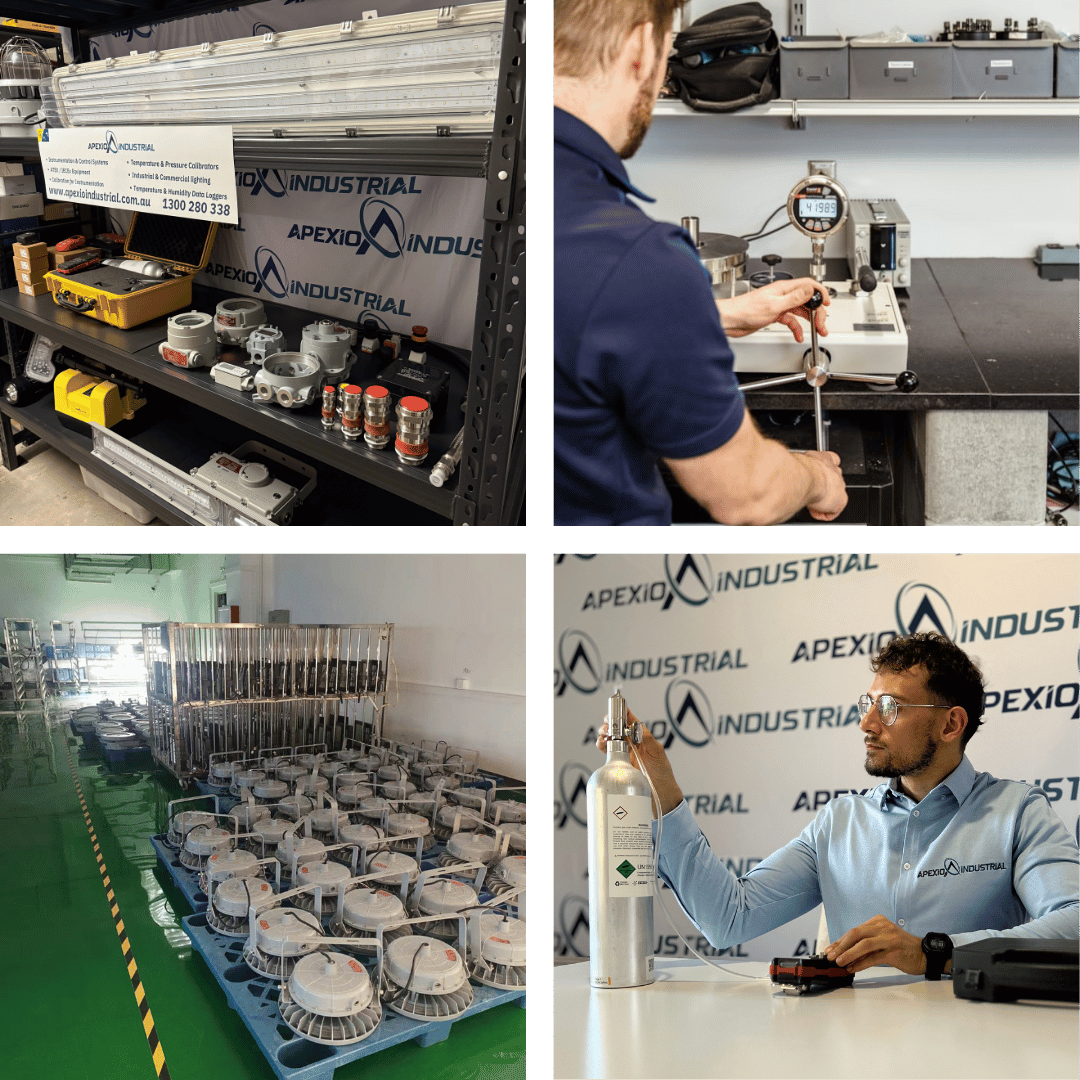

We offer after sales support on a wide range of our products including:

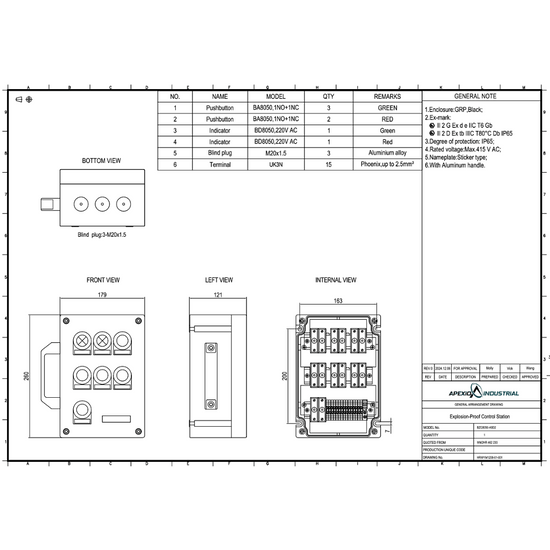

- Design & CAD Drawing

- Product and Component Selection

- Bill of materials

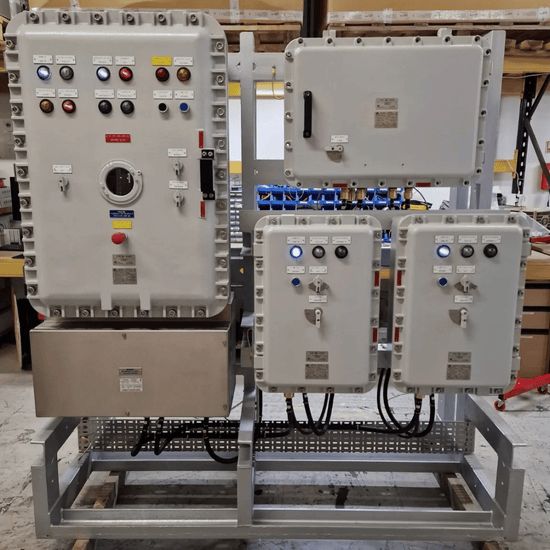

- Engineered Fabrication

- Factory Acceptance Testing (FAT)

- Professional packaging and delivery

- Installation

- Calibration

- Maintenance & Repair

Need help with custom electrical design, fabrication and install ?

-

Design

Leverage our expert resources and state-of-the-art IECEx / ATEX certified workshop to turn your hazardous area electrical design into reality. With unparalleled knowledge and precision, we ensure your project meets the highest safety and compliance standards while delivering exceptional results.

-

Fabrication

Leverage our expert resources and state-of-the-art IECEx / ATEX certified workshop to turn your hazardous area electrical design into reality. With unparalleled knowledge and precision, we ensure your project meets the highest safety and compliance standards while delivering exceptional results.

-

Install

We offer comprehensive turnkey solutions, providing end-to-end services to install, commission, and maintain your systems with precision and expertise. Trust us to deliver seamless integration and ongoing support for reliable performance in any environment.

Pre & Post Sales Support

- We offer technical after sales support to ensure our clients are backed by our team.

- Whether you need support with custom project fabrication, calibration, on-site installation.

- We are here to bring a partnered business relationship with you.

- Our fulfilment warehouse has stocking capabilities for small or large projects.

Introduction to Apexio Industrial

Contact form

AUSTRALIAN OPERATED AND OWNED.

Our Core Values

-

UNPARALLELED SUCCESS

We embrace every challenge as a team with our expertise, and have a proven track record of success when we collaborate.

-

WORK SMARTER NOT HARDER

In order to do great work, we need knowledgeable, well-trained individuals, combined with automation. We are dedicated to not only providing our team with top-notch training, but also world-class equipment to ensure we’re stay at the cutting edge of the industry.

-

TAKE PRIDE

Since the beginning, we have always believed in the quality and longevity of the products we sell and service we provide, and are proud to offer our expertise to all industries.