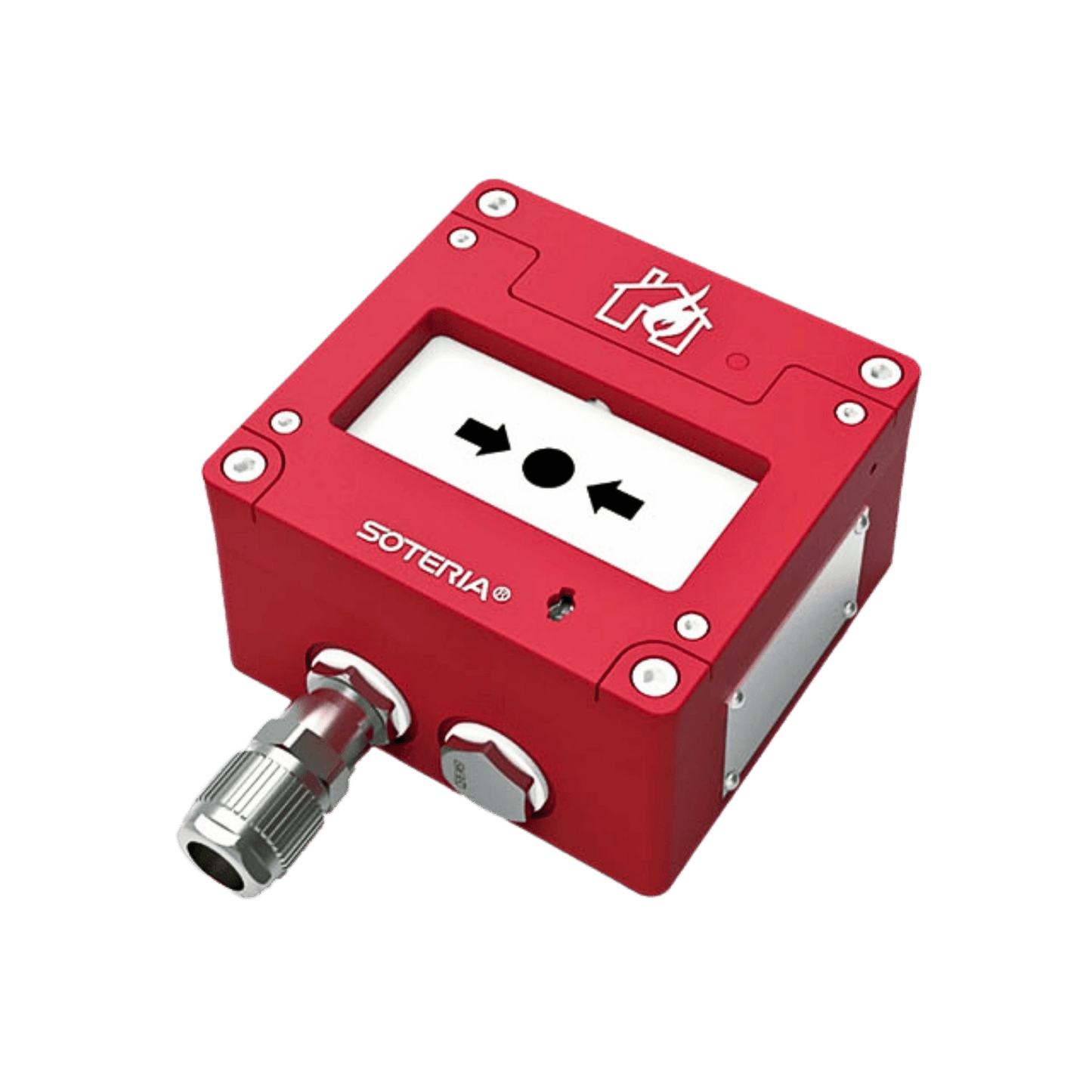

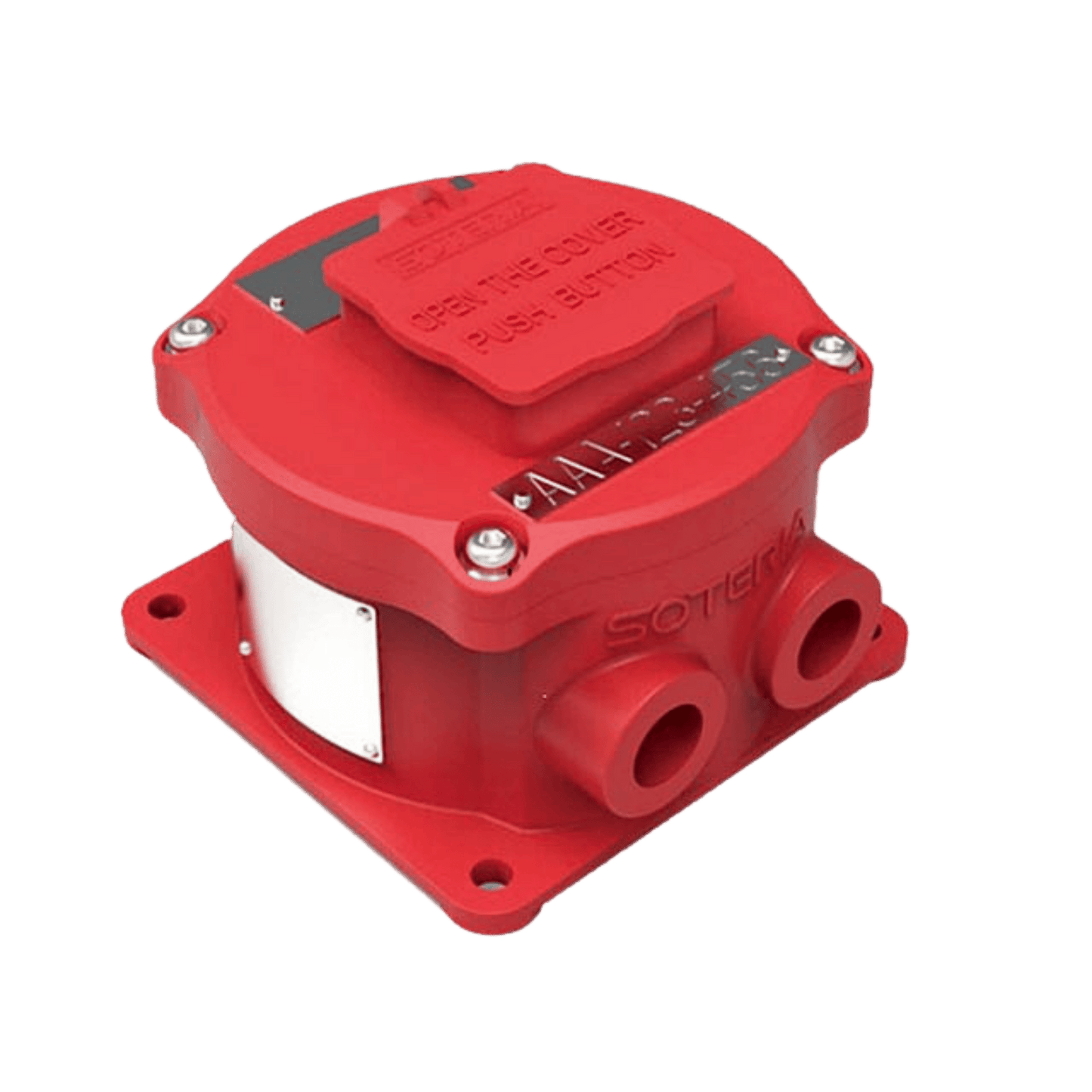

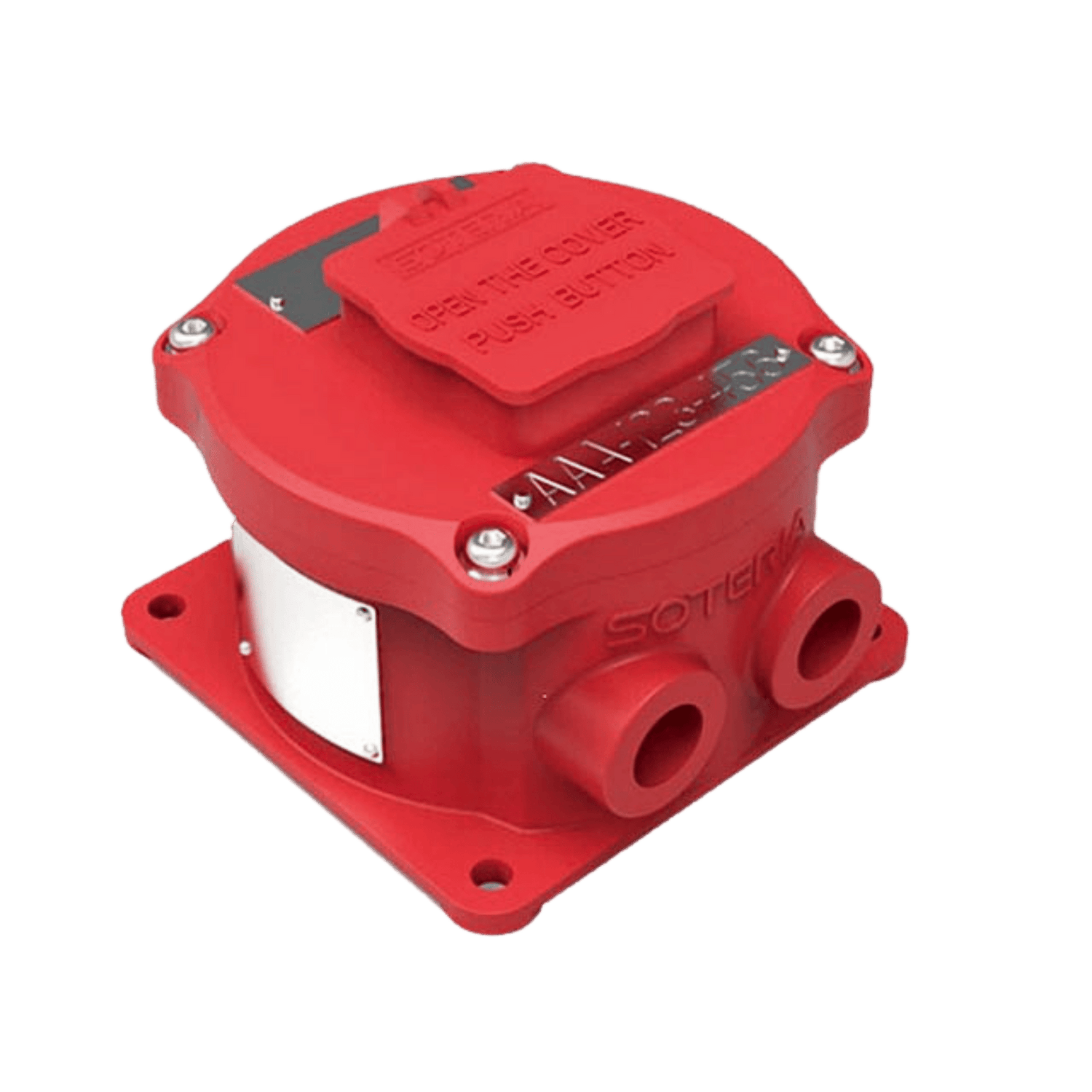

Ex Fire Alarm Break Glass Push Button Call Point IECEx ATEX Hazardous Area Zone 1,2

Ex Fire Alarm Break Glass Push Button Call Point IECEx ATEX Hazardous Area Zone 1,2

Couldn't load pickup availability

The MCP5 Series Explosion-Proof Manual Call Point is a high-performance safety solution designed for use in hazardous areas such as offshore platforms, onshore oil & gas facilities, and chemical processing plants. Engineered to provide manual alarm activation in explosive atmospheres, the MCP5 series offers uncompromised reliability, corrosion resistance, and certification for use in Zone 1 and Zone 2 hazardous environments.

Ideal for initiating fire alarms, emergency shutdowns, FM-200 release/inhibition, and abandon platform alarms, this call point provides fast manual intervention when every second counts.

FEATURES

-

ATEX/IECEx certified for hazardous zones – safe for explosive gas and vapor environments

-

Marine-grade 316L stainless steel housing – superior corrosion resistance in offshore and harsh industrial environments

-

Supports both AC & DC power supplies – flexible integration into existing alarm systems

-

Optional EOL (End-of-Line) resistor – optimized for DC systems and loop supervision

-

Break-glass alarm with test switch – quick activation with inbuilt function testing capability

Collapsible content

Technical Datasheet

Shipping

We aim to process and get your delivery with you as quick as possible -

Shipping rates and delivery times are calculated at checkout.

Guarantee

We aim to provide you with the best quality products, if for an unfortunate product defect we have a 14 day money back return guarantee.

Warranty

• 1 year warranty from the date of purchase.

• Invoice or shipment bill is required to claim the warranty.

• The warranty policy only requires manufacturer to repair the defective product or send substitute for replacement.

• Installation labour, electricity cost and other related cost will not be covered by the manufacturer warranty policy.

• Warranty doesn't cover the defect caused by inappropriate use, especially if directions of the instructions for use are not observed, normal abrasion as well as failures which affect the value or use of the product insignificantly.

Please see our returns policy for more information.

-

Hazardous Area Certified

Certification

- IECEx BAS 20.0086X

- ATEX:SGS20ATEX0183X

Equipment Protection Level

- Ex db IIC T4-T6 Gb

- Ex tb IIIC T85-135°C Db IP66/IP67

- Ex db eb IIC T4-T6 Gb

- Ex tb IIIC T85-135°C Db IP66/IP67

-

FEATURES

- AC or DC power supply

- Optional EOL resistor for DC power supply

- 316 L housing , with excellent corrosion-proof properties and protection

- Broken glass alarm with test switch / Push button

- Addressable

- GRP housing , with excellent corrosion-proof properties and protection

-

Configurations

Physical properties

- Horn material PC/316L stainless steel material

- Ingress protection IP66/IP67

- Cable entry * 2* (Threaded specifications: M20x1.5/ M25x1.5/NPT1/2"/ NPT3/4")

- Weight ≤6kg

Electrical properties

- Tones 32 tones / Customizable

- Audio channels 2 channels

- Rated power 12W

- Sound pressure 113.6 dBA SPL (1W/1m)

- Power supply 24Vdc/100-120Vac/220-240Va

Applications

-

Oil and Gas Facilities

In high-risk environments like refineries, LNG plants, and offshore platforms, explosion-proof call points are used to:

Manually initiate fire alarm systems

Activate gas suppression or emergency shutdown systems (ESD)

Ensure quick human response in areas not fully covered by automated detection

These devices must be explosion-proof due to the constant presence of hydrocarbon vapors and pressurized gases. -

Chemical and Petrochemical Plants

Chemical processing zones often deal with volatile solvents and flammable materials. Manual break glass call points are used to:

Trigger alarms during chemical leaks or fires

Enable local emergency response, particularly in remote workstations

Ensure compliance with strict health, safety, and environmental (HSE) standards -

Mining and Underground Operations

In underground environments with coal dust or methane, standard fire alarm systems are not safe. These call points:

Provide manual alarm initiation during underground fires or equipment malfunctions

Are ruggedized to function under high-vibration and low-visibility conditions

What is a Hazardous Area Manual Break Glass Call Point?

Explosion-proof manual call points (MCPs) are safety-initiating devices housed in flameproof or intrinsically safe enclosures. By breaking the glass and pressing the internal switch, workers can immediately trigger an alarm signal—activating fire alarms, gas detection systems, or emergency shutdowns.

They are certified to ATEX, IECEx, UL, CSA, and other global standards, making them suitable for harsh industrial environments with explosive gases, vapors, or dust.

Why Choose Explosion-Proof Manual Call Points?

Eliminate ignition risks in volatile atmospheres

Reliable, tamper-resistant alarm activation

Integration with existing fire and gas detection systems

Compliant with international safety standards

Quick, clear operation under stress or poor visibility

Introduction to Apexio Industrial

Contact form

-

Pre & Post After Sales Support

After Sales Support

We offer after sales support on all our products including

- Installation

- Configuration

- Maintenance

- Repair

- Calibration

-

Installation and Maintenance

Proper installation and routine maintenance are essential for optimal performance. Considerations include:

- Zoning and certification

- Strategic height and orientation for maximum sound dispersion

- Corrosion, dust buildup, or wiring damage

- Function testing in accordance with regulatory requirements

- Zoning and certification

Our Core Values

-

UNPARALLELED SUCCESS

We embrace every challenge as a team with our expertise, and have a proven track record of success when we collaborate.

-

WORK SMARTER NOT HARDER

In order to do great work, we need knowledgeable, well-trained individuals, combined with automation. We are dedicated to not only providing our team with top-notch training, but also world-class equipment to ensure we’re stay at the cutting edge of the industry.

-

TAKE PRIDE

Since the beginning, we have always believed in the quality and longevity of the products we sell and service we provide, and are proud to offer our expertise to all industries.